![]()

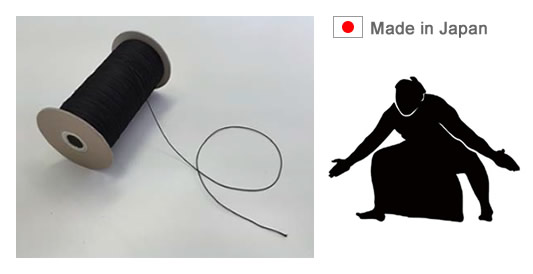

SUMO Wire (durable wire)

Features

1. High tensile strength

The tensile strength of Sumo Wire is 28g/de (24.5cN/dtex, 347kg/mm2), which is 8 times as strong as steel and 3 times as strong as fiberglass, polyester and nylon of the same weight.

2. Dimensional stability

Sumo Wire has stiff and highly oriented molecular structure which leads to high modulus, low creep and low stress relaxation. Due to its low thermal shrinkage, it has good dimensional stability.

3. Heat resistance

Sumo Wire has decomposition temperature of 500°C. It can be used at 200°C and even at 250°C, it maintains more than half of its tensile strength that was measured at room temperature.

4. Chemical resistance

Sumo Wire exhibits high resistance to acids, alkalis and organic solvents. It is also resistant to sea water and steam.

Mechanical Properties

The tensile properties for Sumo Wire are shown in the following Table in comparison with otherindustrial fibers (yarns).

Tensile Properties of Industrial Fibers

| Fibers | Density | Tensile Strength | Tensile Modulus | Elongation at break | ||

|---|---|---|---|---|---|---|

| g/cm3 | cN/dtex | kg/mm2 | cN/dtex | kg/mm2 | % | |

| SUMO Wire | 1.39 | 24.5 | 347 | 530 | 7500 | 4.5 |

| Polyester | 1.38 | 8.1 | 115 | 90 | 1300 | 13 |

| Nylon 66 | 1.14 | 9.1 | 106 | 82 | 1300 | 20 |

| Steel | 7.85 | 3.3 | 275 | 200 | 21500 | 1.9 |

- Wet strength is the same as dry strength.

- Knot strength and loop strength are respectively about 25% and 40% of tensile strength.

- Impact strength is high

- Strength remarkably increases according to the stretching speed.

Specifications

- Material

- Polyamide

- Color

- Black

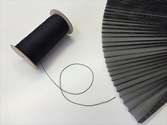

- Application

- Good for using on pleated screen systems

- Minimum Order Quantity

- 1 roll (1,000 m)